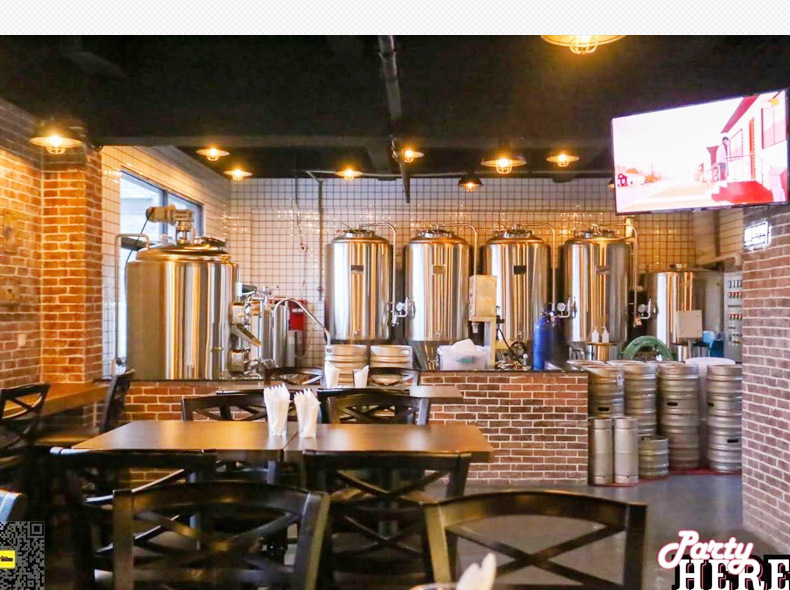

1.Beer brewing equipment

Beer brewing equipment includes: raw material storage equipment 11 malt rice silo, conveying pipe bridge, air dust collector, temperature and humidity monitoring and control equipment, ventilation equipment, weighing and measuring equipment, etc.!

2.Beer packaging equipment Beer packaging equipment includes:

Bottle filling equipment 11 Depalletizers, bottle unloaders, box conveying bridges, bottle conveying bridges, bottle washing machines, filling machines, machines, labeling machines, cartoning machines, stacking machines, CIP washing equipment, and empty bottle detectors , Liquid level detectors and printing equipment, etc.;

The threshold for manufacturing beer brewing equipment is so low that there are now beer equipment manufacturers. Where should so many manufacturers consider the quality of their equipment and how to choose? The editor takes small beer brewing beer equipment as an example to share some knowledge about equipment purchase.

1. The material of the equipment The material of the equipment directly determines the service life of the equipment. When buying the equipment, you must ask about the service life of the equipment, the warranty period, and whether the warranty is the main warranty or the overall warranty. The equipment material should be 34 stainless steel, if it is 21 The price of the equipment varies a lot.

2. Equipment and external polishing and material identification quality We can see the external polishing of equipment, but we often ignore polishing.

(1) Both are 34 or outside, polished to within .4um,

(2) The equipment is made of material 34 or, polished to within .4um, and the outer skin is stainless steel of 4 or 2 series, which is of good quality;

(3) The equipment is 34 or, the unpolished tank body, pipe fittings, and outer skin are 4 or 2 series stainless steel, with average quality;

(4) The equipment is 34 or less, polished/non-polished tanks, and the pipe fittings and the outer skin of the inner liner are 4 or 2 series stainless steel, which is of poor quality. 3. Insulation material The general required material of the fermentation tank is polyester, and the thickness of the insulation layer should not be less than 8mm.

3. There are other materials: rock perlite particles and so on. Different insulation materials affect the insulation time of the tank, the quality of the liquid in the tube, and power consumption.

4. Equipment and valve and pipe fittings generally refer to crushers, refrigerators, control systems, and cleaning systems. When choosing these equipment, you should choose some major manufacturers. Do not choose 21 for quality and valve and pipe materials. The price is poor. A lot of them, and a lot of poor quality.

5. Welding process. Welding is generally divided into: manual argon arc welding at the same time on both sides and manual argon arc welding on one side. Single-sided welding saves nearly one and a half labor costs, but welding is relatively rough. Cost is the requirement of each factory as well as the requirement of the buyer. But if it is too low, you may fall into the price trap for being cheap.

6. In addition to the requirements for the equipment itself, the requirements for the manufacturers are whether the beer brewing equipment manufacturers bear the freight, whether they are installed, the warranty period and maintenance, and whether they teach brewing training, such as the solid-state brewing process of clinker wine source and the solid-state brewing process of clinker wine. The taste is good, and the operation is simple, and the wine yield is high. At the same time, we also need to look at the manufacturer’s qualifications, strength and reputation. The editor here still recommends that you go to the beer brewing equipment factory. You can get it after this set of equipment. Seeing is real and hearing is not.

The above information comes from Shandong Zunhuang brewing equipment manufacturer. If you want to know more, please follow us.