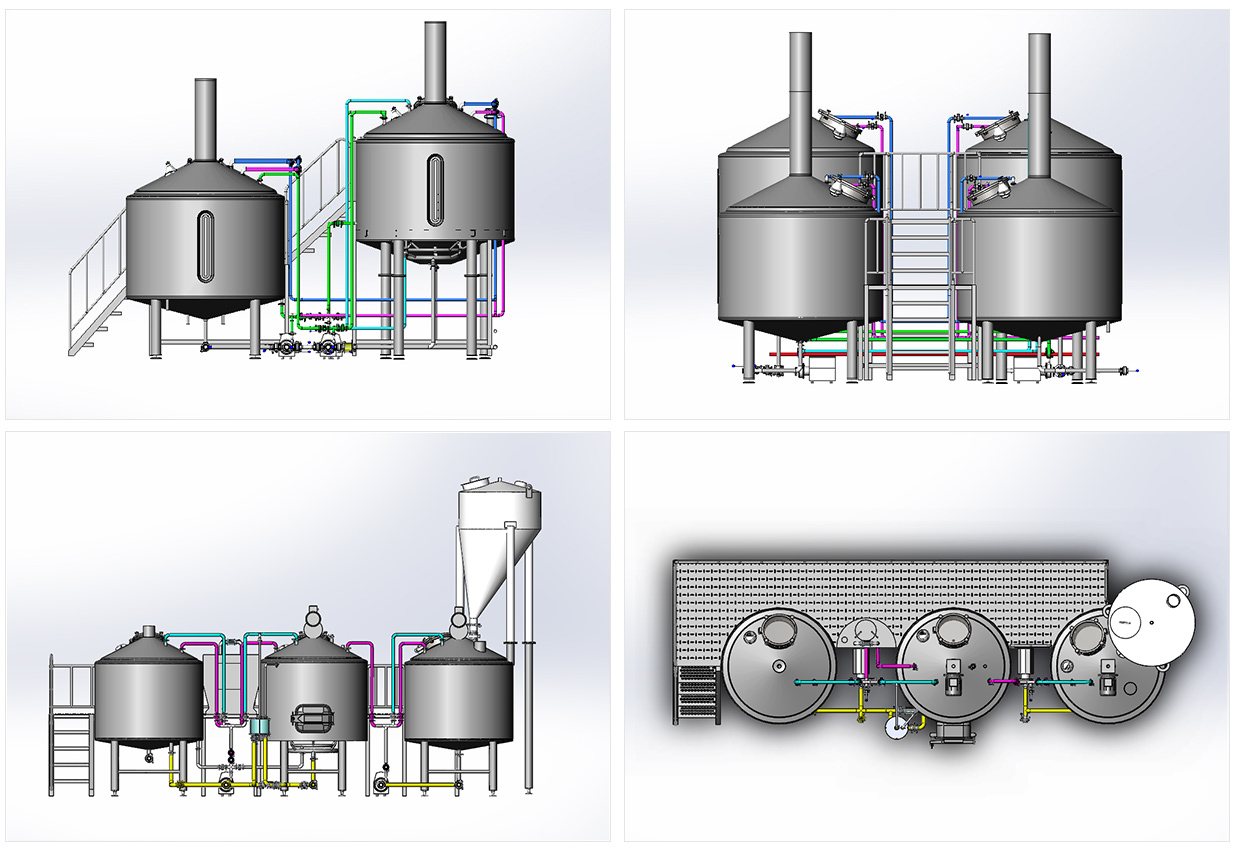

Product introduction: Zunhuang has absorbed the mature and advanced beer brewing technology and technology in Europe and America combined with its own processing technology, and has developed different specifications and different combinations of beer mash equipment to meet the needs of users for beer mashing with different processes and different yields. The design of our mash equipment focuses on improving the quality of wort, energy saving, environmental protection, diversified styles and individualization.

Specifications: 100L, 200L, 300L, 500L, 1000L, 3000L, 5000L, etc. can be customized according to customer needs.

Equipment material: food grade 304 stainless steel

Production cycle: 30-50 days

Zunhuang Company has absorbed the mature and advanced beer brewing technology and technology from Europe and America combined with its own processing technology, and successively developed beer mash equipment of different specifications and different combinations to meet the needs of users for beer mashing with different processes and different yields. The design of our saccharification equipment focuses on improving the quality of wort, energy saving, environmental protection, diversified styles and individualization.

|

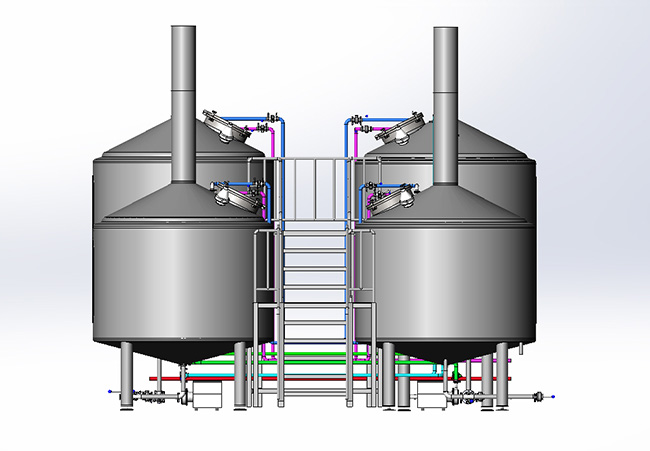

Main configuration |

Mixing, raker, milling sieve, frequency conversion wort pump, buffer tank, two-stage plate heat exchanger, yeast adder, oxygenation device, cleaning device, waste washing ring pipe, outlet door, operating platform, PT -100 temperature display, valve pipeline, glass manhole, screw-down side manhole, LED sight light |

|

Optional |

Material water mixer / tiller lifting device / hop filter tank / steam condensing device / wort collection device / recoil device |

|

Product outsourcing |

Outsourcing can be made of stainless steel original plate, oil film drawing plate, red copper plate, rose gold plate, etc. It can also be customized according to customer special needs |

|

Common model |

100L, 200L, 300L, 500L, 1000L, 3000L, 5000L, etc. can be customized according to customer needs |

|

Heating method |

Electric heating / steam heating / direct fire heating (customers choose according to the situation) |

|

Controlmethod |

Manual control/semi-automatic control |

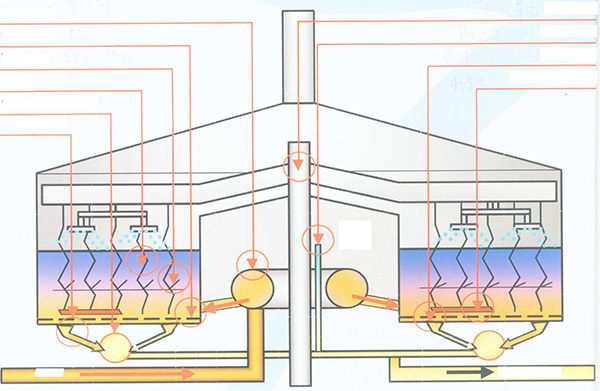

Purpose and requirements of mash

The purpose of mash is to soak out as much soluble substances as possible in the raw materials, and create conditions that are conducive to the action of various enzymes, so that many insoluble substances become soluble substances under the action of enzymes and dissolve out, thereby obtaining as much dissolution as possible The proportion of the components contained in it is appropriate. For example, the ratio of sugar to non-sugar: light beer is controlled at 1:0.4~0.5; dark beer is controlled at 1:0.5~0.7. The ratio of high, medium and low molecular nitrogen: high molecular nitrogen 15-20%; medium molecular nitrogen 20-25%; low molecular nitrogen 55-60%.

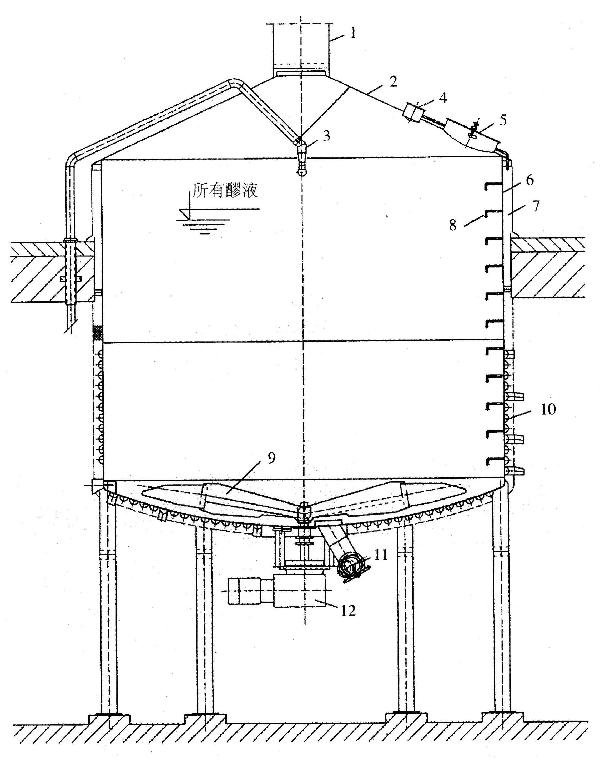

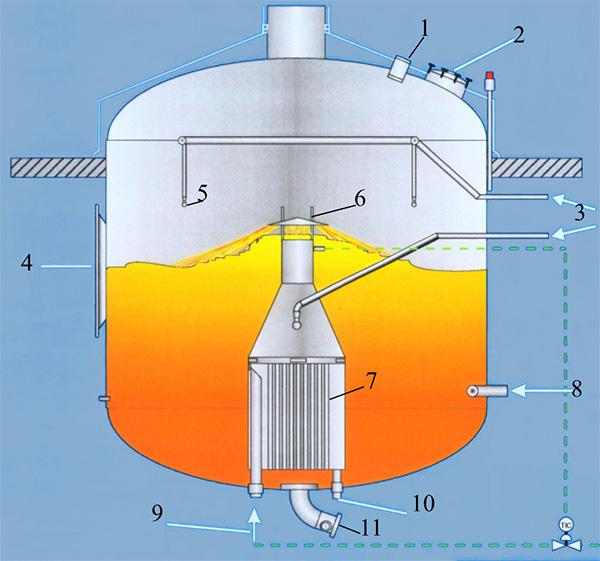

1-Exhaust cylinder 2-Top cover of steam exhaust pot 3-CIP cleaning 4-Internal lighting 5-Sight hole 6-Pot wall jacket 7-Insulation layer 8-Climbing bar 9-Stirrer 10-Heating pipe 11-Mash Import and export 12-drive motor

Leaching saccharification

1. Single mash constant temperature leaching method

The feeding temperature (that is, the mash temperature) is about 65°C, and the mashn is heated to a filtration temperature of 78°C after 1 to 2 hours, and the filtration is performed. There is no protein decomposition stage, so it is only suitable for malt with relatively complete protein decomposition.

2. Single mash heating leaching method

Feed at 35-37°C, soak the raw materials, directly heat up to 50°C for protein decomposition, then slowly heat up to 65°C, 72°C for segmented saccharification, and then heat up to 78°C for filtration. The leaching mash method requires the use of well-dissolved malt, which is especially suitable for brewing whole malt beer and top-fermented beer. 70% of British beer is the above fermented beer, all using the leaching saccharification method.

3. Double mash leaching saccharification method

After the mash and the gelatinized mash are mixed, the mash is no longer boiled, but is directly heated in the mash tun to reach the required temperature at each stage of mash; since only part of the mash is boiled, the high-molecular-weight malt substance in the endosperm cell wall and Less dissolution of other impurities, the prepared wort has light color, low viscosity, soft taste and high degree of fermentation. It is especially suitable for brewing light and refreshing beer and dry beer; simple operation, short saccharification time, and can be completed in three hours .

Cook out mash

The characteristic of the boiled mash method is to heat a part of the mashed material to the boiling point in batches, and then mix it with the rest of the unboiled material, so that the temperature of the whole mash is raised to the temperature required by different enzymes in stages. Reach the final mash temperature.

According to whether auxiliary materials are added in the mashing process, the cooking mashing method can be divided into single mash cooking method and double mash cooking method; according to the number of times of mashing, single mash cooking method and double mash cooking method can be divided into three, Two times and one time cooking method.

Key issues in the saccharification process

(1) Oxidation problems in the process from feeding to mashing;

(2) Mechanical action caused by stirring, pumps and poor pipeline transportation;

(3) Poor convection and mixing of mash;

(4) Excessive heating temperature, coupled with poor convection (temperature of heating interface);

(5) Cavitation of the pump;

(6) The dead zone in the pipeline is easy to acidify the wort and form butyric acid;

(7) When the mash is boiling, the steam will remove the undesirable substances;

(8) The harm caused by optimized mash and too short leaching mash process will result in a weak beer taste and loss of beer characteristics;

(9) From an economic point of view, it can be adopted: use turbid washing residue water, add hot water process or partial mash method to increase the feeding temperature and carry out acidification treatment.

Two stages of wort filtration

After the mash process is over, the decomposition of the macromolecular substances in the malt and auxiliary materials has been completed, and the dissolved soluble and insoluble substances in the mash should be separated quickly to obtain a clarified wort. At the same time, people also expect a higher leaching rate.

The wort filtration process can be roughly divided into the following two stages.

First wort filtration: the wort obtained by filtering the saccharified mash with the lees as the filter layer is called the first wort.

Filtration of lees and wort: Use hot water to elute the washable extract remaining in the lees.

Basic requirements for wort filtration

Quickly and thoroughly separate the soluble extracts in the mash. Minimize the influence of wheat husk polyphenols, pigments, bitter substances, and high molecular weight proteins, fats, fatty acids and β-glucans in the malt into the wort, so as to ensure a good taste and high clarification of the wort degree.

1-Mash inlet 2-Temporary storage tank for grains of wheat 3-Cultivation machine 4-Cleaning ring pipe 5-Lighting 6-Manhole 7-Exhaust pipe 8-Regulating valve 9-Sight glass 10-False bottom cleaning pipe 11- Filter pump 12-lifting and driving device of the tiller

Changes in the boiling process of wort

Dissolution and transformation of hop bitter substances; formation and separation of coagulable protein-polyphenol complexes; evaporates excess water to make the wort reach the specified concentration; sterilizes the wort; completely destroys the enzyme activity and fixes the wort components The color of the wort increases; the acidity of the wort increases; the formation of reducing substances; the change of the content of dimethyl sulfide (DMS) in the wort.

1.Illumination 2-Manhole 3-CIP inlet 4-Sight glass 5-Cleaning ball 6-Umbrella cover 7-Internal heater 8-Wort inlet 9-Steam inlet 10-Condensate water outlet 11-Wort outlet

Wort boiling time: The wort boiling time should be determined according to the beer variety, technology and quality requirements.

Boiling strength: The boiling strength of wort should reach 8%-10%. It is an important factor affecting protein coagulation, and has a significant impact on the brightness and coagulability nitrogen content of wort.

pH value: pH value is closely related to protein aggregation, wort color and flavor. The pH value is in the range of 5.2~5.6, protein can generally achieve good aggregation effect.

Add hops: add hops according to the amount and time specified by the process.

Wort concentration: before boiling, during boiling, 10 minutes before the end of boiling, and after boiling, determine the amount of wort and the concentration of wort.