Product introduction: The heating method of beer equipment, sufficient heat source supply and precise temperature control system play a vital role in the entire mash process and boiling process, and have a direct impact on the smash boiling effect. The heating system of Zunhuang Company is equipped First-line brand boilers and hot water tanks made by precision work provide a stable and efficient heat source supply for the entire equipment.

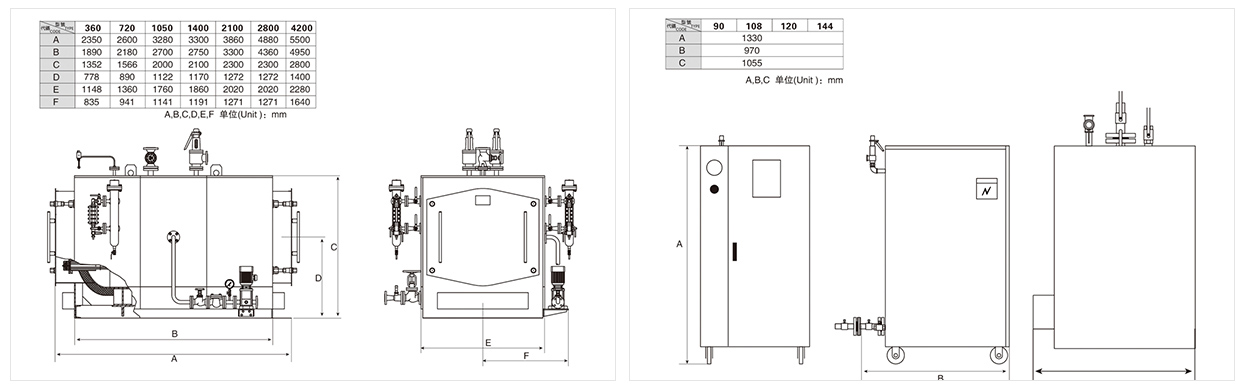

Specifications: 2000L hot water tank equipped with boiler; 3000L hot water tank is equipped with boiler; 5000L hot water tank is equipped with boiler; 10000L (and above) hot water tank is equipped with boiler.

Equipment material: stainless steel 304/spray

Delivery time: 30-50 days

The heating mode of beer equipment, sufficient heat source supply and accurate temperature control system play an important role in the whole mash process and boiling process, and have a direct effect on the mash and boiling effect.

Wort boiling

Preheating: after filtering wort without passing the heater surface, the amount of steam at this time is low.

Initial boiling: the wort begins to boil, the initial boiling time should not exceed 30 minutes. At this stage and the steam output is not sufficient enough, the still in sparging progress. This stage is to prepare for evaporation, once the sparging is finished, evaporation can be carried out immediately.

Evaporation: boiling stage, in which the amount of steam opens to the maximum, keeping the wort in a violent boiling state, evaporating 100 L of water on average (5~8) minutes. This stage should be maintained for about 90 minutes. Not less than 75 minutes, not more than 120 minutes.

Effect of Boiling Strength

High boiling strength can improve the utilization rate of raw materials, shorten the boiling time of wort, help protein solidification, volatilize some ingredients with bad flavor, and improve the utilization rate of hops. However,if the boiling intensity is too high and the tumbling is too intense, which will strengthen the oxidation effect, make the wort color deeper and reduce the reducibility, lead to the increase of the volatilization loss of hop oil and the insufficient aroma of hops, and destroy the flocculent thermosetting.

Process control of wort boiling

Wort boiling time: Wort boiling time should be determined according to the variety, process and quality requirements of beer.

Boiling strength: the boiling strength of wort should reach 8%~10%. It is an important factor affecting protein solidification and has obvious influence on the brightness and coagulability nitrogen content of wort.

PH value: pH value is closely related to protein condensation, wort color and flavor. The pH value is in the range of 5.2~5.6, and the protein can achieve good condensation effect.

Add hops: add hops according to the amount and time specified in the process.

It is very important to heat the mash tun, boiling pot, and hot water tank. Steam heating is the best choice. Steam heating has a uniform heating surface and wort color will not be too deep. This needs to be equipped with boiler.

The electric heating pipe can be used on the equipment below 1000 liters. By equipped with auxiliary measures such as stirring, the equipment above 1000 liters can be heated by steam.

At present, the boiler is a standard product, the quality is relatively stable, it is suggested to choose a good brand. At the same time, the use of the boiler must be matched with softened water equipment, otherwise the scale in the boiler will be full in a few months, which will seriously affect safety.