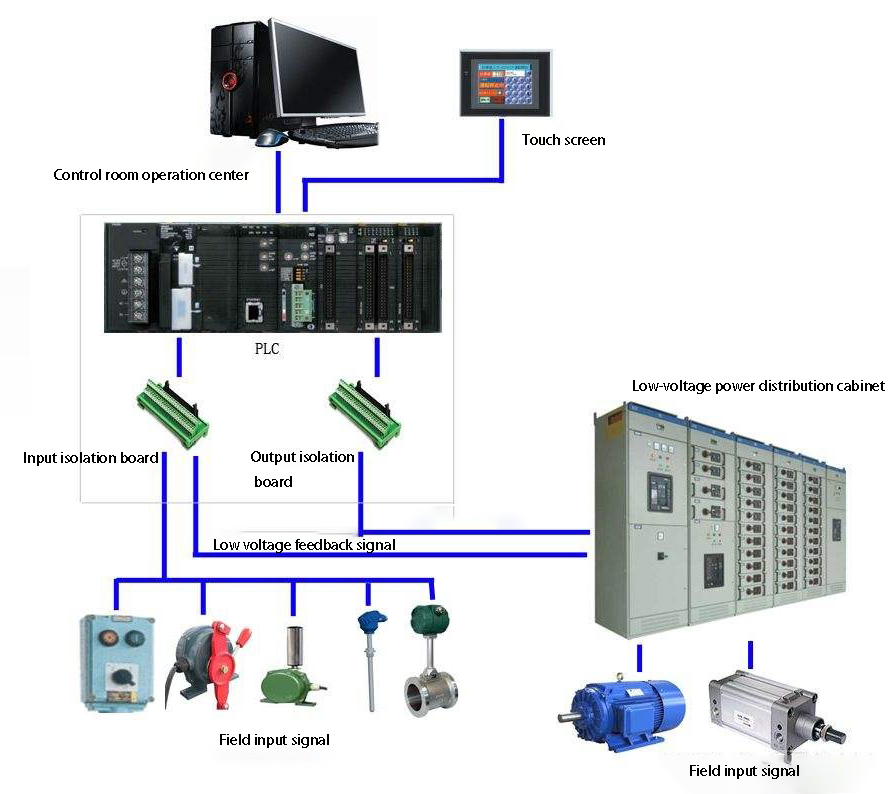

Product introduction: Zunhuang company adopts PLC control system and DSC intelligent control system to realize centralized control and discrete control. remote control. It can be programmed and set according to the process to achieve different process goals. Our control system can be customized according to customer needs.

Specifications: Intelligent instrument control cabinet, PLC control cabinet, DSC intelligent control system, etc. can be equipped according to equipment requirements.

Equipment material: stainless steel/spray

Production cycle: 30-50 days

Zunhuang adopts PLC control system and DSC intelligent control system to realize centralized control and discrete control. remote control. It can be programmed and set according to the process to achieve different process goals. Our control system can be customized according to customer needs.

Intelligent instrument control cabinet

Voltage: 380v/50HZ/three-phase five-wire.

Dimensions: 700*400*1700mm

The automatic and manual control conversion can be realized freely on the control cabinet;

Temperature and pressure control accuracy are ±0.1℃, ±0.01MPa respectively

Mash power system: control heating, stirring, tiller, wort pump, saccharification, filtration temperature display

Signal line, control line

PLC control cabinet

Dimensions: 700×400×1700;

The free setting of mash temperature control, boiling temperature, and hot water tank temperature section can be edited through the PLC touch screen;

Ice water pump/cold water pump/refrigerator/chiller opening and closing etc.;

The control system controls the opening and closing of the mash, motor stirring, tiller, mash pump, and filter pump.

You can edit the free setting of the temperature control of the fermentation tank, the ice water tank, and the sake tank through the PLC touch screen;

Ice water pump/cold water pump/refrigerator/chiller opening and closing, etc.;

DSC intelligent control system

The DCS system includes three major parts: a controller with I/O components, a communication network and a man-machine interface. Due to the high degree of automation and reliability of DCS, almost all newly-built large craft breweries use it as the main control system. DCS will eventually integrate almost all control systems such as PLC to establish a unified operating platform to make information transmission faster , The configuration is more transparent, the variety of spare parts is reduced, and the management and maintenance are unified.