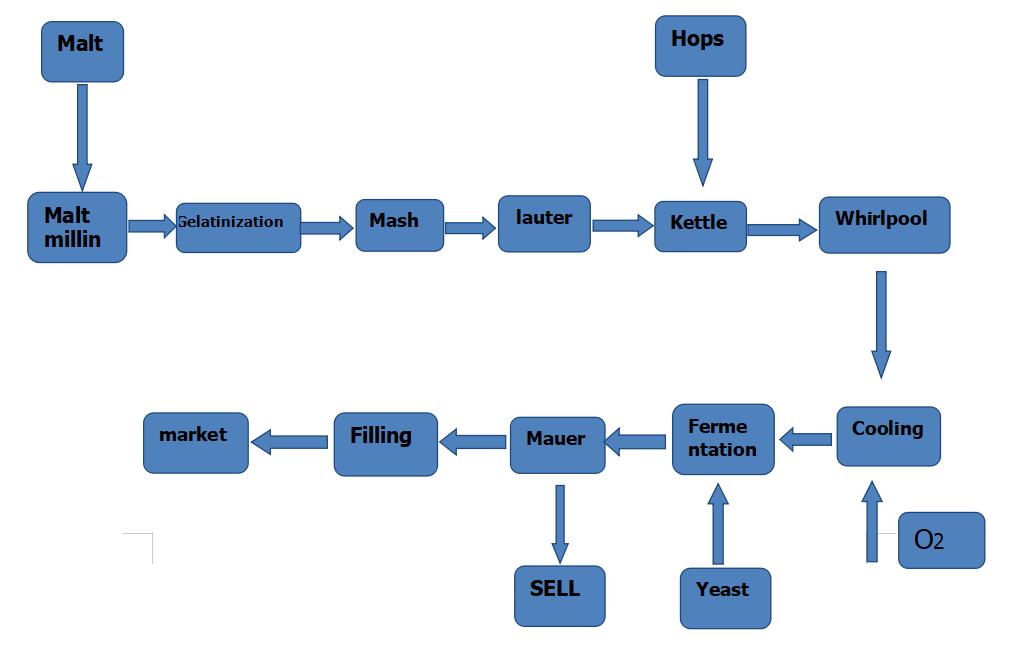

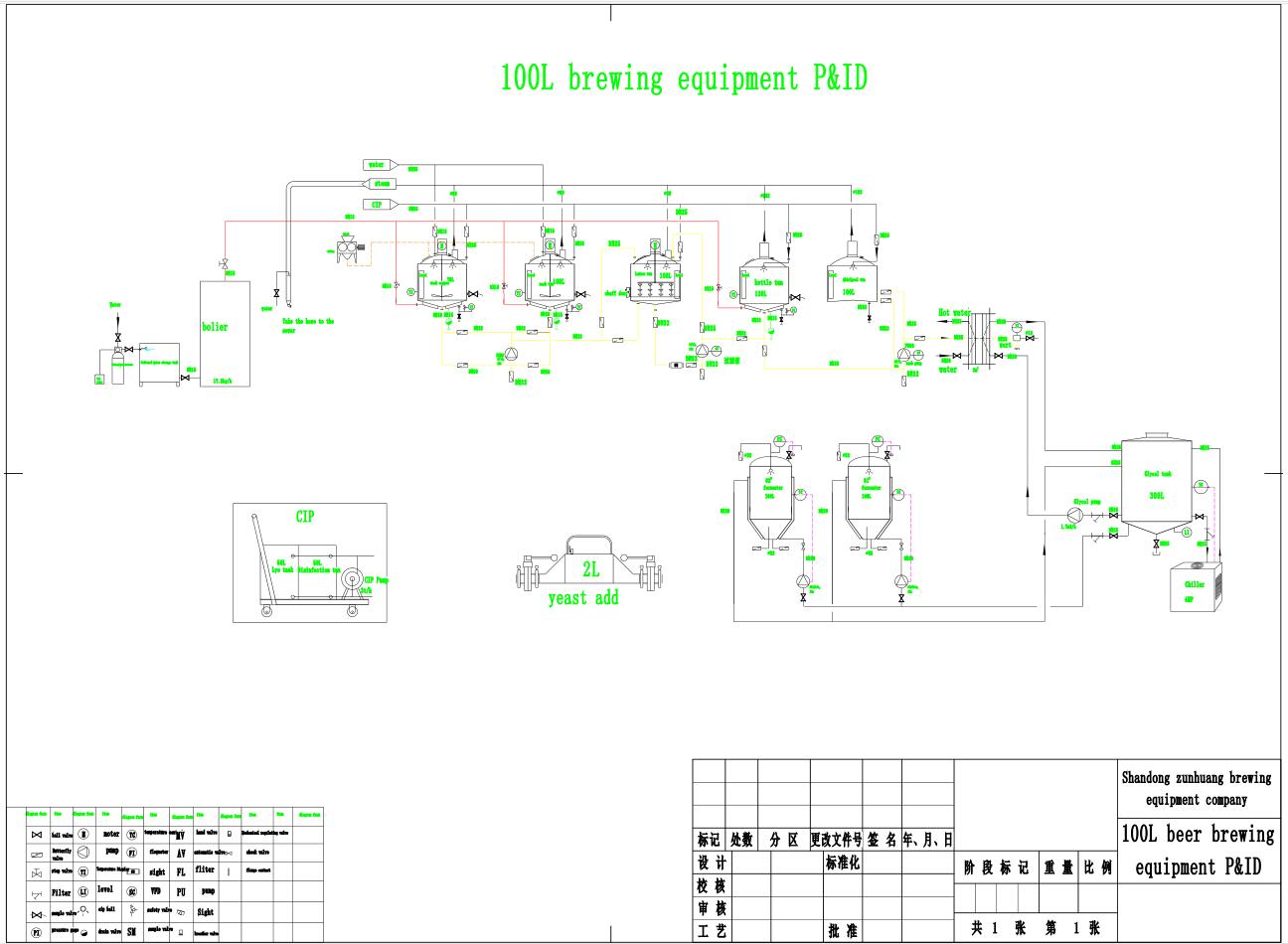

The ZHS series beer experimental training equipment has comprehensive system configuration, advanced equipment performance, accurate parameters, flexible operation, safe and stable, which can show the entire process of beer brewing, allowing students to experience the full-featured production control of the brewery in the laboratory process.It is mainly composed of raw material processing system, mash system, heating system, fermentation system, refrigeration system, control system, filtering system, filling system, CIP cleaning system etc. It is a set of standard version of brewery fermentation process Training line.

Raw material processing system:The system mainly includes a double-roller malt milling (using rice auxiliary material brewing process plus a rice grinder) to realize the pretreatment of brewing raw materials.

Mash system: It is mainly composed of gelatinization tun, mash tun, lauter tun, kettle tun, whirlpool tun, plate heat exchanger, pump, etc., and each component is connected through a pipeline to complete the various processes of the mash process;

Heating system: Mainly choose electric steam generator and supporting softened water treatment device to provide heat energy supply for mash process;

Fermentation system:It is mainly composed of 6-8 temperature-controlled cone-shaped fermentation tanks with jackets. It adopts Maitreya plate jacket for cooling and temperature control, polyurethane foaming insulation, and mainly completes the entire fermentation process;

Refrigerating system:It is mainly composed of ice water tank, refrigeration unit, ice water pump, etc., cooling the fermentation tank through the circulating pipeline, and cooling the hot wort through the plate heat exchanger;

Control system: The control system completely adopts Siemens programmable controller PLC, industrial computer and other automatic control components. It has the characteristics of convenient centralized management, discrete control, strong anti-interference, strong reliability and can be connected to various PLCs and remote computers. The pilot production and scientific research requirements of universities, technical colleges, scientific research institutes, and breweries can also be designed and produced according to user needs;

Filtering system:Contains candle-type diatomaceous earth machine, membrane filter, bright beer tank, etc., which can meet the requirements of coarse filtration and fine filtration of fermented beer, realize the clarification of the wine body, and prepare for filling;

Filling system: Because there is no sterilization equipment, the test line generally adopts fresh beer barrel filling to ensure the freshness and stability of the wine body. It usually includes a barrel washing machine and a barrel filling machine. Simple plate type wine filling devices can also be equipped to realize a small amount of filling. In addition, small filling equipment such as small quantities of PET bottles, glass bottles, tinplate barrels, and banquet barrels can be customized according to actual requirements;

CIP cleaning system: It is mainly composed of alkali tank, disinfection tank, cleaning pump, control box and trolley, which can realize automatic cleaning of saccharification system, fermentation system and sake system, and the operation is convenient and quick.

The experimental training equipment adopts the most cutting-edge process design, the equipment and the pipeline layout have no dead ends, the equipment is processed fine, and the welding accuracy reaches the sanitary standard; the interior adopts multi-mirror polishing, and the exterior adopts stainless steel polished matte treatment, which is beautiful and practical; the pipeline adopts Sanitary stainless steel pipes are welded on one side and formed on both sides. It can not only fulfill the complete fermentation process teaching requirements, but also help users develop new varieties of test beer, test new beer materials, develop new technologies, study the proliferation of beer yeast and the influence of yeast concentration on beer.

Product description:It is suitable for home brewing test, each batch is small, the operation requirements are higher, and manual operation is mostly used.

Specification:50 liters, 100 liters, 200 liters, 500 liters and more than 500 liters.

Equipment material:Food grade 304 stainless steel.Production cycle: 20-40 days

Product description:It is suitable for experimental teaching in scientific research institutes of universities and colleges, with complete system, convenient teaching and simple operation, but the quantity of each batch is small.

Specification:50 liters, 100 liters, 200 liters, 500 liters and more than 500 liters.

Equipment material:Food grade 304 stainless steel.Production cycle: 20-40 days

Product description:It is suitable for experimental teaching in scientific research institutes of universities and colleges, with complete system, convenient teaching, simple operation, and moderate batch quantity.

Specification:50 liters, 100 liters, 200 liters, 500 liters and more than 500 liters.

Equipment material:Food grade 304 stainless steel.Production cycle: 20-40 days

Product description:It is suitable for experiment teaching, variety development, and pilot production in scientific research institutes of universities, brewery experiment centers, etc. It has strong integration of production, education and research, convenient and quick operation, and can complete pilot production in each batch.

Specification:50 liters, 100 liters, 200 liters, 500 liters and more than 500 liters.

Equipment material:Food grade 304 stainless steel.Production cycle: 20-40 days