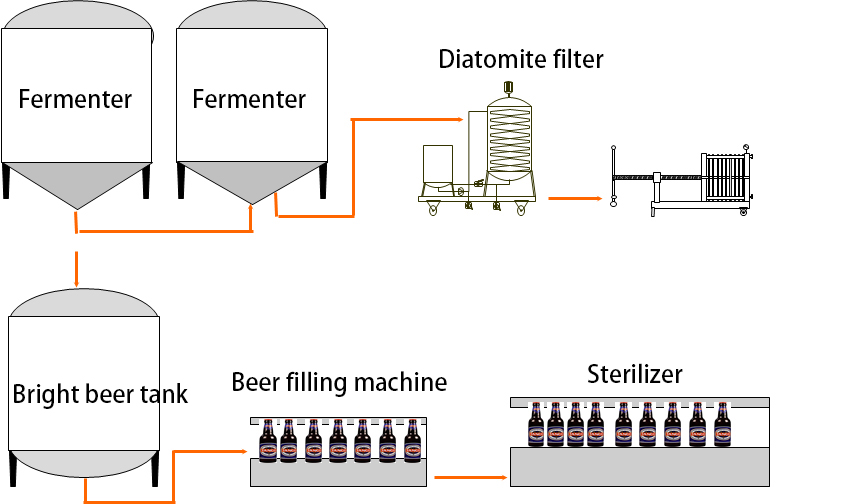

The beer filtration system produced by Shandong Zunhuang Brewing Equipment Co., Ltd. combines the needs of different users with different types of filters and bright beer tanks, which can meet the requirements of product purity, ensure that the original wort concentration of the product is qualified and maintain. The foam performance and bitterness value of beer improve the sensory quality of beer and enhance its brightness.

Specifications: 1000L, 2000L, 5000L, 10000L etc. can be customized according to special needs.

Equipment material: Sanitary 304 stainless steel

Production cycle: 30-50 days

The beer filtration system produced by Shandong Zunhuang Brewing Equipment Co., Ltd. combines the needs of different users with different types of filters and bright beer tanks, which can meet the requirements of product purity, ensure that the original wort concentration of the product is qualified and maintain. The foam performance and bitterness value of beer improve the sensory quality of beer and enhance its brightness.

The goal of beer filtration

Remove turbid substances, such as protein, protein-tannin complex, polyphenol, β-glucan and some pasty substances;

Remove microorganisms, such as cultivated yeast, wild yeast, bacteria, etc.;

Isolate oxygen; eliminate the influence of iron, calcium and aluminum ions;

Reduce the impact of mechanical effects on beer (easy to cause the formation of jelly);

Beer filtration theory

After fermentation or post-treatment of mature beer, the residual yeast and protein coagulum are deposited on the bottom of the wine tank, and a small amount is still suspended in the wine. These substances will precipitate out of the beer during subsequent storage, causing the beer to become cloudy. Therefore, it must be removed through a filtration process.

Beer filtration is a physical separation process, which is related to the appearance and taste of beer, as well as biological and non-biological stability.

After filtering, the beer has a clear and transparent appearance, rich in luster, making it more attractive; at the same time, it can endow the beer with good biological and non-biological stability, so that it will not change in appearance at least during the shelf life, thereby ensuring the beer The appearance quality is perfect.

Principle of filtration

Beer filtration is a physical process that uses filter media to separate and remove tiny particles suspended in beer from the liquor, so that the beer is clear and transparent without suspended matter.

When beer is filtered, the turbid beer becomes clear by trapping solids through the filter medium. The power of filtration is the pressure difference between the inlet and outlet of the filter. The pressure of beer through the filter medium is constantly changing, and changes with the porosity of the filter medium.

The pressure at the inlet is always higher than the pressure at the outlet. The greater the pressure difference, the greater the resistance of the filter. This resistance prevents the filtration process, especially at the end of the filtration, the pressure difference rises quite quickly.

When beer is filtered, the filtering speed is directly proportional to the pressure difference and the filtering area, and inversely proportional to the fluid viscosity and the thickness of the filter medium.

Type of filter material

Metal filter screen or textile: there are different kinds of metal screens, crack screens or special-shaped metal wires and metal or textile braids installed in parallel on the candle diatomaceous earth filter.

Filter plate: The filter plate can be made of fiber, cotton, diatomaceous earth, perlite, glass fiber and other materials. There are many types of filter plates, which can meet the needs of different filtration precisions, up to aseptic filtration.

Membrane materials: more and more applications of membrane filtration. Many materials are used to make membranes, such as polyurethane, polypropylene, polyamide, polyethylene, polycarbonate, acetate, and other materials. The film is very thin (0.02~1μm).

Diatomaceous earth: Diatomaceous earth is the most widely used filter aid in the modern beer industry. This is a sedimentary rock ore composed of algae siliceous cells. It is made after ore crushing, high temperature calcination, air separation and classification. A kind of porous, light filter aid, its main components are silicon dioxide, aluminum oxide.

Perlite: Perlite is an amorphous mineral rock formed by the volcanic ash of volcanic eruption. It is molten potassium, sodium, and aluminosilicate, which has strong chemical inertness. The perlite produced by crushing, calcining and sorting perlite ore has properties very similar to diatomaceous earth, but is different from diatomaceous earth. These particles are more regular in shape and are trilobal.

The main method of beer filtration

Cotton cake filter; diatomaceous earth filter; cardboard filter; two-flow filter; cross-flow filter; sterile plate-and-frame diatomaceous earth filter, etc.

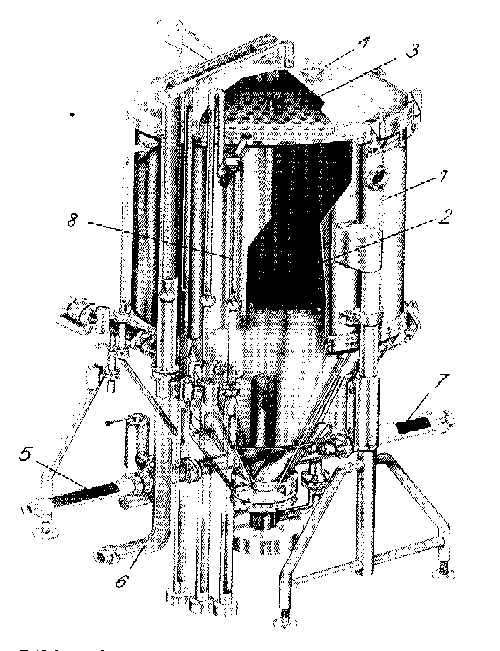

Candle diatomite filter

The filter candle wick is a filter material, and the filter medium-diatomaceous earth is pre-coated on the candle wick. For filtering, the spiral wire is wound around the candle wick in the radial direction, and the wire spacing is 50-80 μm. The slender filter candle wick is more than 2m long.

Since a large number of candle wicks are installed in the filter, the formed filter area is very large and the filter efficiency is very high.

1-Filter tank; 2-Hanging candle wick; 3-Fixed candle wick board; 4-Filter cover; 5-Unfiltrate inlet; 6-Filtrate outlet; 7-Waste diatomite turbidity outlet; 8-Exhaust pipe;

Horizontal disc diatomite filter

Horizontal disc type diatomaceous earth filter is also called leaf filter. In the filter, there is a hollow shaft, and multiple discs (filter units) are fixed on the hollow shaft, and the discs are used for filtering.

From the cross-sectional view of the horizontal disc type diatomaceous earth filter, the filter disc can be clearly seen, and the structure of the horizontal filter disc is also diverse.

In the horizontal disc type diatomaceous earth filter, the filter support material is a filter disc woven from chromium-nickel steel material, and the aperture of the metal screen is 50-80 μm. This filter only has a metal screen fixed on the upper surface of the horizontal disc.

1-Tank with sight glass; 2-Clear liquid flowing out of hollow shaft; 3-Filter unit; 4-Spacer ring; 5-Small support foot; 6-Pressing device; 7-Filter disc type for remaining residual liquid; 8-Lower inlet; 9-With the upper inlet of the distributor; 10-the main outlet of clear liquid; 11-Residual liquid outlet; 12-Exhaust port; 13-Hydraulic device; 14-Hydraulic system motor; 15-Shaft seal; 16-Collar cleaning brush/discharge port; 17-Waste diatomite discharge sleeve; 18-Waste diatomite discharge device; 19-Spray washing device;

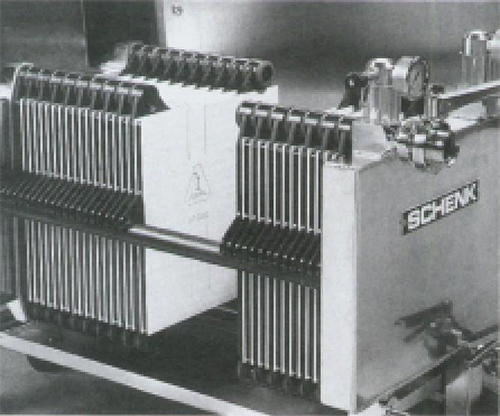

Cardboard filter

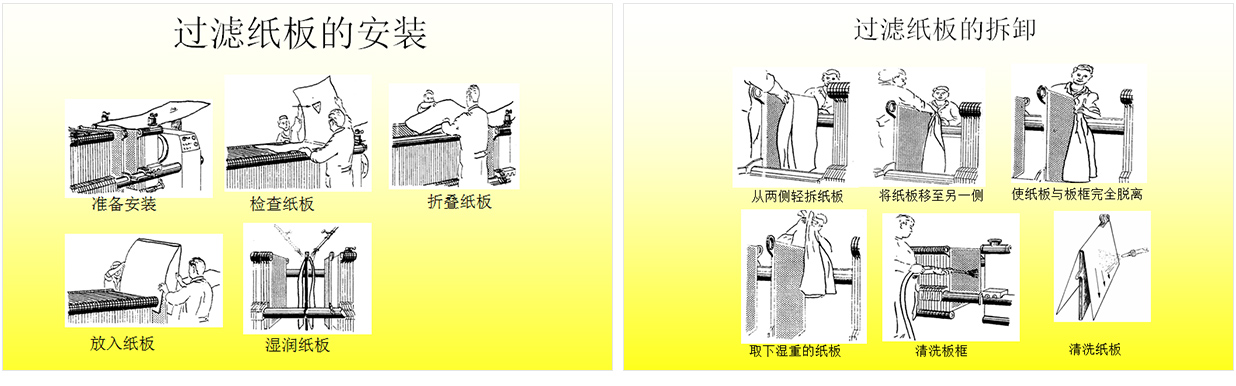

Operation process of cardboard filter

1. Install the cardboard.

2. Carefully press the water through the filter plate to expel the air.

3. Sterilize with hot water at 80~90℃ for 20 minutes or use steam. After sterilization, cool to the same temperature as the wine before filtering the wine.

4. The resistance continues to increase during the filtration process. When the filtration is completed, the filtration pressure difference should not exceed 0.13MPa.

5. When filtering beer, properly apply back pressure to prevent carbon dioxide from expanding in the board and destroying the strength of the cardboard.

6. After filtering the wine, backwash with water at 50~60℃. If diatomite is used for pre-coating, turn on the machine first, and then turn off the waste soil for cleaning.

7. The cardboard can be reused after being sterilized by hot water at 80~90℃ for 15~25 minutes.