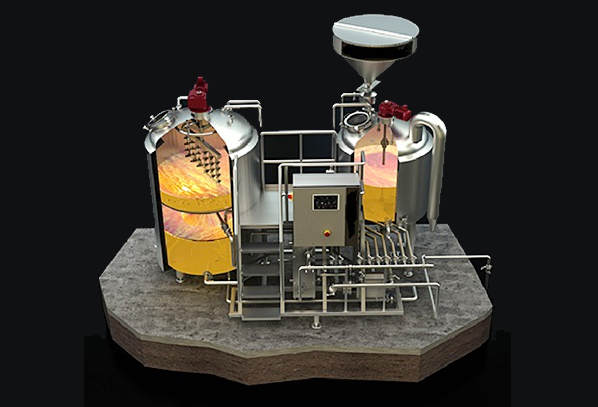

ZH series hotel beer equipment is suitable for hotels, guesthouses, bars and other entertainment venues. It can brew various types of beer for you, such as dark beer, yellow beer, wheat beer, nutritious beer and other beer. While tasting high-quality pure fresh beer, customers can also watch the luxurious and elegant shape of the equipment with handicraft characteristics, creating a simple, natural and open social environment for the hotel.

Such equipment generally has a volume of 100 liters, 200 liters, 300 liters, 500 liters and more than 500 liters.

The ZH series hotel beer equipment has a beautiful appearance and conforms to the Chinese aesthetics. The mixing and tilling knife reducer and tilling knife are upgraded to horizontal, the equipment operation is more stable, and the jacket design is added to fully filter out the vibration during use and keep the equipment running smoothly.

The heating area of the saccharification/boiling pot is large and the heating speed is fast.

The position of the lauter tank is high, which can realize natural filtration (wort is filtered by gravity), the filtration speed is fast, and the wort is clear and bright. Even if the operation is wrong, there will be no compaction of the grain layer or deformation of the board.

The whirlpool tank is a tangential feed. Because it is a special whirlpool, the design does not consider too much influence conditions, so the separation effect of hop lees and hot coagulum is better.

When the wort is filtered, the mash/brew tank can prepare the lees water, and the lees can be washed while filtering, which can shorten the mash time by 30-50 minutes.

Generally, two batches can be brewed in one day. If you consider staying up late and working overtime, you can brew 3 to 4 batches a day. During the peak beer sales period, you can brew more wine in the shortest time.

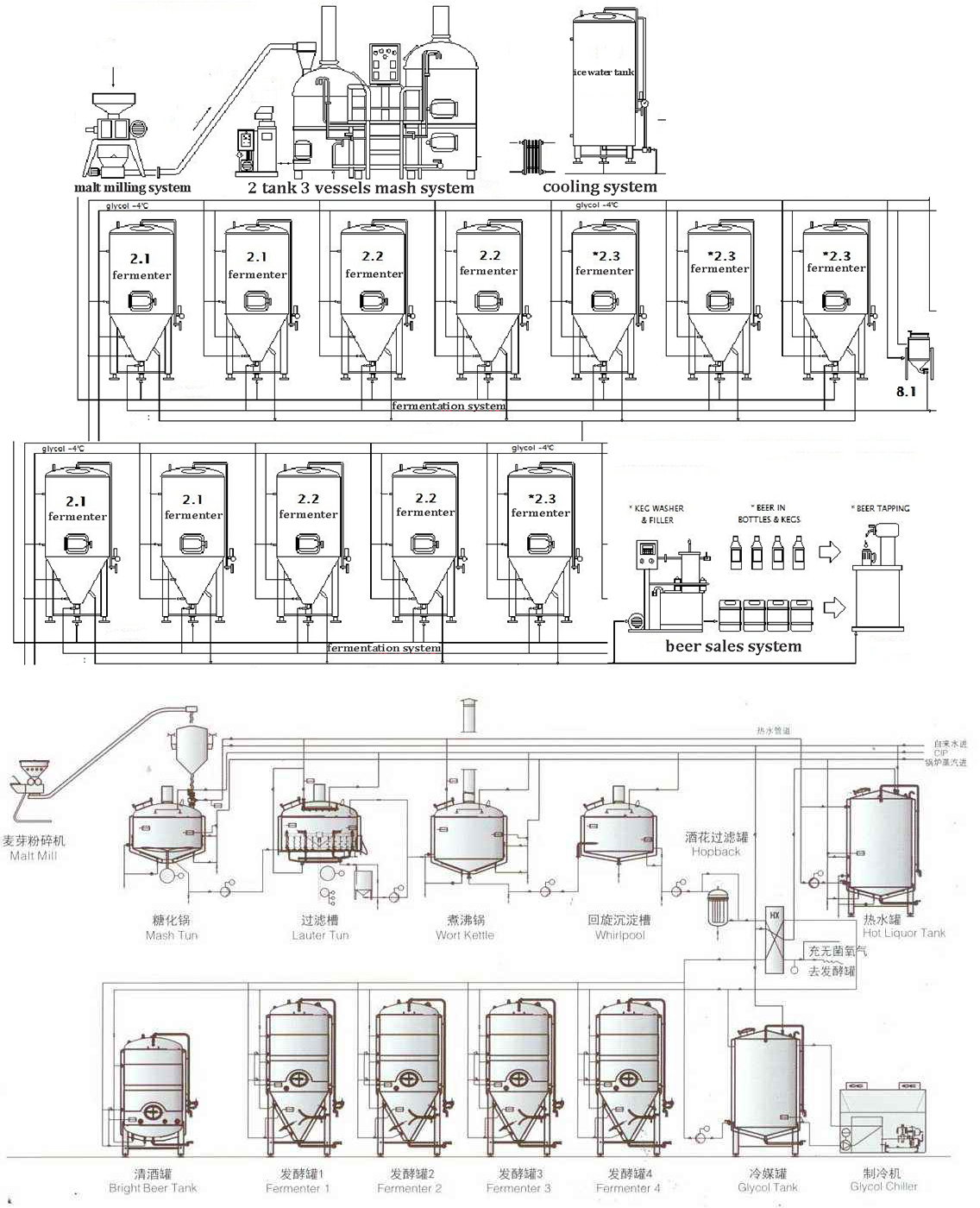

Product introduction:This type of equipment is generally composed of mash/brew tank and lauter tank, and mash/brew kettle has both whirlpool tank Function, or mash/lauter, brew/whirlpool composition.

Specifications:100 liters, 200 liters, 300 liters, 500 liters and more than 500 liters

Equipment material:food grade 304 stainless steel.Production cycle:20-40 days

Product introduction:This type of equipment is generally mash/brew tank, lauter tank/whirlpool tank, and its lauter whirlpool tank is actually composed of an upper and lower two-layer structure, the upper layer is the lauter tank, and the lower layer is the whirlpool tank.

Specifications: 100 liters, 200 liters, 300 liters, 500 liters and more than 500 liters

Equipment material:food grade 304 stainless steel.Production cycle:20-40 days

Product introduction:There are many combinations of this equipment, the commonly used combinations are as follows: mash+lauter+brew/whirlpool tank; mash/lauter+brew kettle +whirlpool tank; mash/lauter+brew kettle/whirlpool tank+ hot water tank; mash/brew kettle+lauter+hot water tank.

Specifications:100 liters, 200 liters, 300 liters, 500 liters and more than 500 liters

Equipment material:food grade 304 stainless steel.Production cycle:20-40 days