Product Description

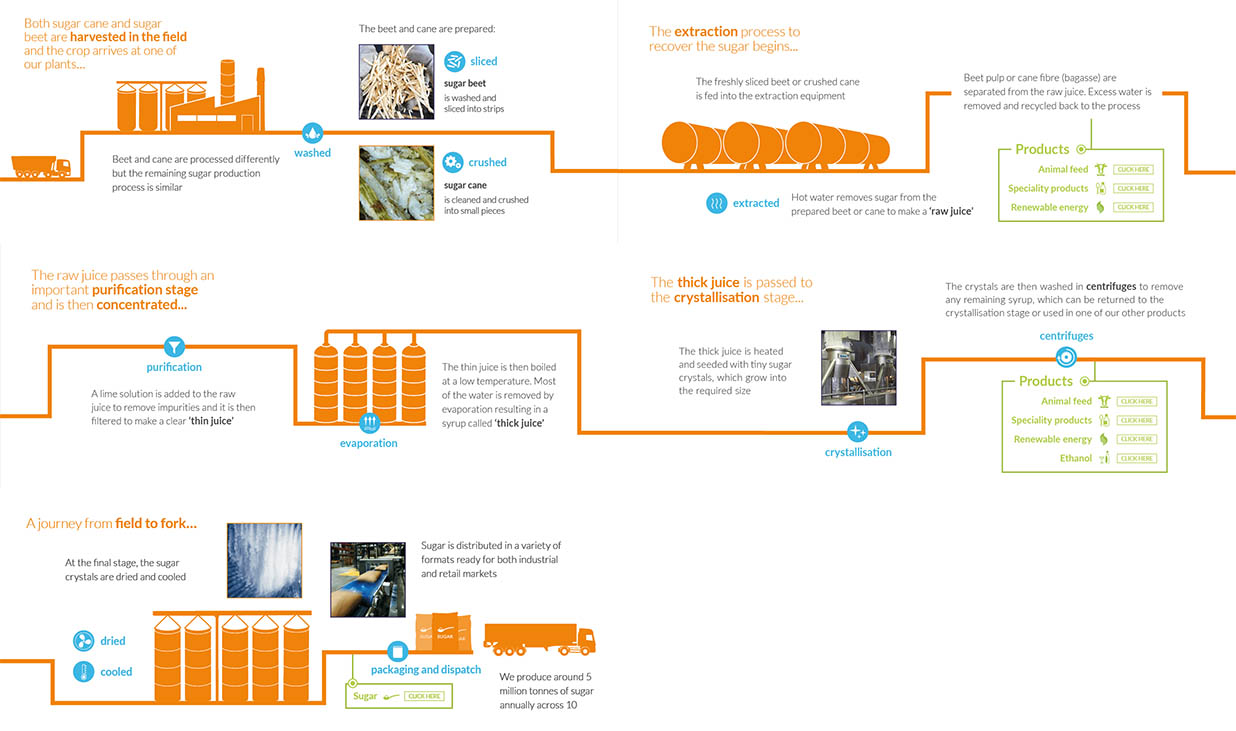

Beet sugar manufacturing is a process in which sugar beets are used as raw materials, and sugar products such as white granulated sugar and soft white sugar are made through processes such as juice extraction, purification, evaporation, crystallization, honey separation, and drying. Its working principle is;

1. Taking wet transportation as an example for sugar beet pretreatment and exudation. Beets are washed by a vegetable washing machine after being cleared of soil, weeds, and stones. After washing the beet, the shredded vegetable enters the continuous diffuser through a shredder. The leaked sugar juice is sent to the next section after slag removal and heating.

2. The cleaning process includes two steps: ash filling and sulfur bleaching.

a) Ash filling: Using the bicarbonate method. Ash addition and purification include two main processes, one is ash addition and carbon saturation. Lime is added and sugar juice is carbonated to remove impurities. The saturated carbon juice is filtered, and the filtered sludge is collected as solid waste; The second process is carbon dioxide saturation. The filtered juice enters the carbon dioxide saturation tank for secondary saturation, and CO2 is introduced to further precipitate and separate the excess lime in the sugar juice. The carbon dioxide juice is filtered, and the filtered juice enters the next sulfur bleaching process. The filtered sludge is collected as solid waste.

b) Sulfur bleaching: The main purpose of sulfur bleaching is to reduce the color of sugar juice. The sugar juice quickly enters the sulfur bleacher to generate negative pressure. The cooled SO2 gas is sucked in and fully mixed with the sugar juice in the pipeline, and the absorption of SO2 gas is quickly completed. The SO2 gas introduced into the sugar juice first dissolves in water to form strong reducing sulfuric acid, and then the pigment is reduced to colorless compounds to decolor the sugar juice. The decolorized sugar juice is filtered and sent to the evaporation process.

3. The evaporation of sugar juice generally adopts a three effect, four effect, or five effect evaporation system. After evaporation, the water is removed and the syrup is concentrated into syrup

4. Boiled sugar syrup is further heated and concentrated under vacuum conditions, and a supersaturated concentrated solution containing white sugar crystals is obtained. The finished white sugar is then crystallized, separated, dried, and screened

Capacity

|

No .

|

item

|

parameter

|

|

1

|

capacity

|

3000~15,000 tons per year

|

|

2

|

yield

|

White sugar

|

|

3

|

raw material

|

beet

|

Final product specification

|

No.

|

item

|

parameter

|

|

1

|

White sugar

|

3000~15,000 tons per year

|

|

2

|

Sucrose content

|

≥99.6~99.8%

|

|

3

|

Reduced sugar

|

≤0.03~0.10%

|

|

4

|

Conductivity ash

|

≤0.03~0.10%

|

|

5

|

Drying weight loss

|

≤0.06~0.12%

|

|

6

|

Color value,IU

|

≤30~170

|

|

7

|

Turbidity

|

≤3~9

|

|

8

|

Insoluble in water impurities

|

≤20~50mg/kg

|