The yeast expansion equipment produced by Shandong Zunhuang Brewing Equipment Co., Ltd. is made of high-quality stainless steel and high-quality valves, pipe fittings. It is used for the expansion of yeast cultivation in the brewery, and can effectively preserve the yeast on the production site to ensure the yeast purebred. The expansion system of colleges and universities adopts PLC automatic control to meet the different needs of different beer manufacturers for yeast. There are multiple forms and models such as two-stage expansion and three-stage expansion.

Specifications: 25L, 30L, 300L, 400L, 500L, 3000L, 4000L, etc. can be customized according to special needs.

Equipment material: Sanitary 304 stainless steel

Production cycle: 30-50 days

The yeast expansion equipment produced by Shandong Zunhuang Brewing Equipment Co., Ltd. is made of high-quality stainless steel and high-quality valves, pipe fittings. It is used for the expansion of yeast cultivation in the brewery, and can effectively preserve the yeast on the production site to ensure the yeast purebred. The expansion system of colleges and universities adopts PLC automatic control to meet the different needs of different beer manufacturers for yeast. There are multiple forms and models such as two-stage expansion and three-stage expansion.

The sequence of expanding and cultivation of beer yeast

Oblique interview tube (original strain) → Fuchner bottle or test tube culture → Pasteur bottle or triangular flask culture → Carter tank culture → Hansheng tank culture → Yeast expansion tank → Yeast propagation tank → Fermentation tank.

The above-mentioned cultivating from oblique interview tube to Kaspersky tank is the laboratory expansion stage; Hansheng tank will be the expansion stage of the production site.

Technical requirements for laboratory expansion

All culture utensils must be thoroughly scrubbed, tampon plugged, and sterilized by dry heat. The sterilization temperature is about 170℃;

The culture medium should be the wort added with hops on site, heated and boiled and clarified by adding protein. After intermittent steam sterilization, it can be stored in an incubator at 25°C for 2 to 3 days, and it can be used after it is proved that it is free of pollution;

Each time the expansion dilution factor is about 10 times or less;

After each transplantation, the development of yeast cells should be checked under microscope;

With the expansion of each stage of cultivation, the cultivation temperature is gradually reduced to adapt to the on-site fermentation conditions; • (6) Each expanded cultivation stage should be cultured in parallel: 4 to 5 test tubes, 2 to 3 pasteurizers, card There are 2 pots, and the superior ones are selected for expansion.

The basic requirements of the yeast expansion device are as follows

Achieve sufficient ventilation and oxygen saturation. As for the continuous or intermittent method, it depends on the corresponding ventilation cycle;

Perform uniform mixing and distribution in the expansion tank to ensure violent contact between yeast cells, wort and bubbles;

Appropriate temperature control during the expansion phase and when it is cooled to the inoculation temperature at the end of the expansion;

Expand cultivation under good microbial conditions;

Appropriate measurement and adjustment techniques ensure a reproducible process.

Several principles for expanding yeast cultivation

Strain conditions, culture temperature, culture time, ventilation and oxygen supply, nutrients, culture expansion times, and sterile wort.

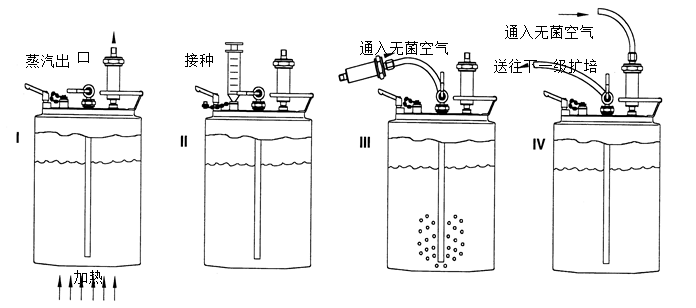

Carter tank

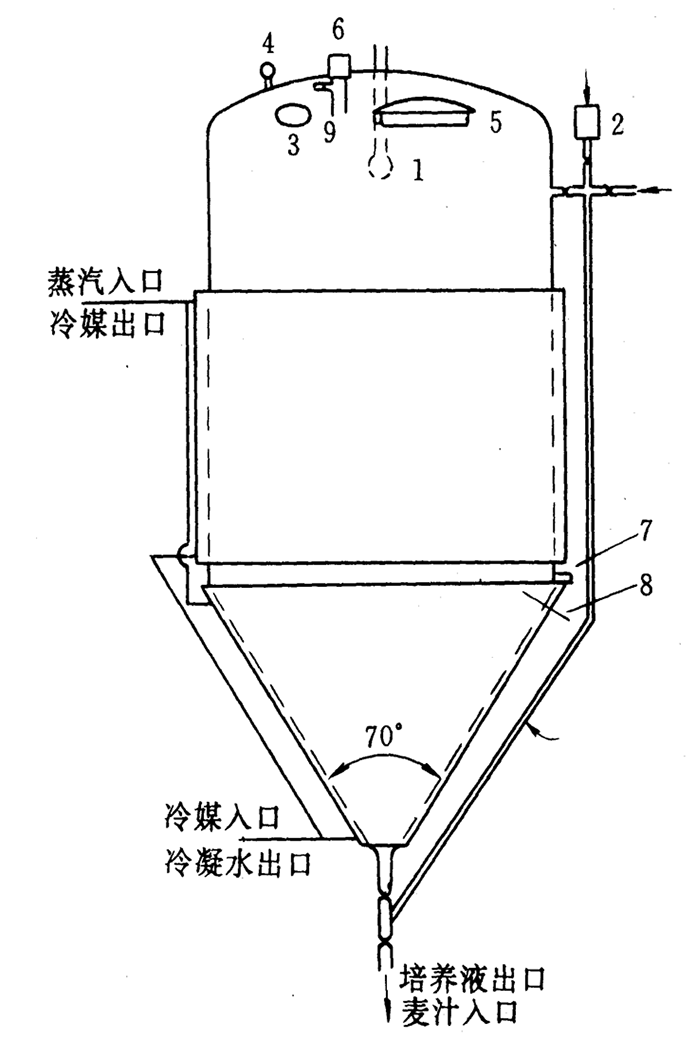

1-Air filter 2-Grip handle 3-Insulated handle 4-Sampling valve 5-Inoculation head with rubber film

Carter tank yeast culture process

Ⅰ:Heating(加热); Steam outlet(蒸汽出口);

Ⅱ:Vaccination(接种);

Ⅲ:Filling sterile air(通入无菌空气);

Ⅳ:To the next level of expansion system(送往下一级扩配系统);

1-Cleaning tube; 2-Secondary air filter; 3-Sight glass; 4-Pressure gauge; 5-Manhole; 6-Breath valve; 7-Simple valve; 8-Temperature sensor; 9-Air discharge port;

Technical parameters of yeast expansion equipment

|

Yeast expansion system |

Name |

Model |

Material |

Quantity |

Working type |

Marking |

|

Primary expansion tank

|

300L/400L |

304 |

1 |

Automatic

|

PU form

|

|

|

Secondary expansion tank

|

3000L/4000L |

304 |

1 |

Automatic

|

PU form

|

|

|

CIP cleaning tank

|

500L |

304 |

1 |

Automatic

|

---- |

|

|

Carter tank

|

25L |

304 |

1 |

---- |

---- |

|

|

Valve and pipe

|

---- |

304 |

Matching

|

---- |

Connect the tube plate |

|

|

Automatic control elements

|

---- |

---- |

Matching

|

Automatic

|

---- |

|

|

Automatic control elements

|

---- |

---- |

Matching

|

Automatic

|

---- |

|

|

Scope of application:1. The first and second expansion system with 300L×3000L tanks, is suitable for breweries with an annual output of less than 20,000 kiloliters. 1. The first and second expansion system with 400L×4000L tanks, is suitable for breweries with an annual output of more than 30,000 kiloliters.

|

||||||