Installation and commissioning of equipment

1. Matters needing attention

1.1. During the hoisting and transportation of the equipment, ensure that no one is standing under the equipment.

1.2. The equipment must be installed on a stable foundation. The depth of the foundation can be determined by the user according to the local geological conditions. If the equipment is placed upstairs, before installing the equipment, please confirm whether the floor can bear the weight of the equipment when it is fully filled with feed water or beer liquid. If it cannot bear the weight, place it in a different place or take strengthening measures.

1.3. Equipment layout should be reasonably arranged in accordance with process requirements, with ease of operation as the main standard.

1.4. During the installation of the equipment, any component should be installed under the power off condition, and warning signs can be hung if necessary. It is not allowed to start commissioning and commissioning before determining whether there are personnel or potential safety hazards within the dangerous range of the equipment. During commissioning, the pump valve should be opened by jog to avoid damage to the machine.

1.5. The main power supply of this equipment adopts 380V, 50Hz power supply, please check the local power supply. The wires and cables used in the equipment installation must use the standard cables specified by our company, and the wiring must be connected in strict accordance with the wiring diagram.

1.6. The power distribution control equipment should be placed near the operating location, where it can be quickly stopped in the event of a failure. As long as the device is connected to the power source, even if the device is turned off at this time, the power is not actually turned off. If you do not plan to use the machine for a period of time, please cut off the power of the device from the main power supply.

1.7. During the use of this equipment, some components will generate a high temperature of about 100°C, which may cause burns.

1.8. A large amount of steam will be generated during the beer production process. The indoor production equipment must have a good exhaust device to prevent a large amount of steam from condensing, which greatly increases the indoor air humidity, corrodes indoor objects, and even affects pumps, electromagnetic valves, and control equipment. And other power facilities cause harm and bring serious safety hazards.

1.9. The washing liquid used for cleaning and disinfection is a highly corrosive liquid. The operator must wear protective gloves and a face mask during operation. If the liquid accidentally splashes on the body, it should be cleaned with plenty of water immediately and consult a doctor for diagnosis.

1.10. When the crusher is running, do not put your hands in the hopper to prevent the machine from being crushed.

Equipment maintenance

1. Precautions for use

1.1. It is strictly prohibited to use Cl-detergents or disinfectants for equipment cleaning.

1.2. If the equipment is not used for a long time, please clean the equipment thoroughly before decommissioning. After the water has drained, close the valves. Please clean the equipment thoroughly before restarting it after being used for a long time. Repeat the cleaning several times.

1.3. The heat exchanger should be disassembled and cleaned after long-term operation or after a long period of non-use. Metal brushes are forbidden when cleaning, and it is forbidden to bend, twist, step on, or squeeze the heat exchanger plates. Replace in time.

1.4. The equipment should regularly check the wiring and grounding of each motor and pump to ensure that the wiring is correct. Check the oil level of the geared motor and hydraulic device, and add lubricating oil to the stirring motor regularly according to the instructions. Regularly check whether the connections of the mixing and tilling knife are tight. The pumps used must not be idling or reversed. If the pump is leaking, replace the pump seal in time.

1.5. Frequently check whether there are foreign objects in the hopper of the crusher, check whether the fasteners on the crusher are loose, the tightness of the crusher's drive belt and the reliability of the safety protection devices. Clean the grinder roller regularly.

1.6. Frequently check whether the electric heating equipment is normal, and the liquid level is less than the specified level. Never turn on the heating! When the equipment is running, warning signs should be hung on the top of high-temperature pipelines such as wort and the top of the saccharification equipment to prevent burns.

1.7. It is forbidden to extract wort in large flow during filtration, which may damage the sieve plate. When the equipment is not in use, no weight shall be placed on the screen plate to avoid deformation of the screen plate. Ensure the smooth operation of each mechanical part when the equipment is running.

1.8. Check the plate heat exchanger at any time for leakage, leakage, or liquid leakage. If there is any leakage, repair it immediately.

1.9. Pay attention to the alkali water concentration in the alkali water tank at any time. If the alkali water concentration is too low or too turbid, it cannot be used for washing and should be replaced in time.

1.10. Check all pipeline valves at any time, and repair or replace in time if any leakage is found.

1.11. Frequently check the indications of the instruments on the switchboard. For the digital temperature control meter temperature correction, mercury (or alcohol) thermometers can be used to calibrate the temperature to ensure the accuracy of the process parameters.

1.12. The saccharification equipment should be rinsed with water in time after each use, and the saccharification pipeline, plate heat exchanger and wort pipeline should also be rinsed.

1.13. It is strictly forbidden to grab and climb the equipment process pipeline, cooling pipeline and exhaust pipe.

1.14. When the equipment is shut down for maintenance, the power and steam should be cut off and warning signs should be hung.

1.15. Clean the ice water pipe filter once a month.

1.16. The safety devices of gas boilers should be inspected locally, and internal descaling should be carried out once a quarter.

2. Common problems and solutions

2.1.

|

Common Problem

|

The Reason

|

Solution

|

|

Wort is unclear or difficult to filter

|

1. Malt quality is not good (low saccharification power).

|

1. Choose good quality malt.

|

|

2. The crushing effect is poor.

|

2. Correctly implement the principle of "breakable but not broken".

|

|

|

3. Inaccurate saccharification temperature and insufficient time.

|

3. Correct and strictly control the saccharification temperature and time.

|

|

|

4. The concentration of mash is too high.

|

4. Control the amount of water added for saccharification according to process requirements.

|

|

|

5. The filtering method is wrong.

|

5. Control the precipitation time of lees and the speed of wort reflux.

|

2.2. Common faults and troubleshooting methods of electrical appliances

|

Serial Number

|

Failure Phenomenon

|

Measures

|

|

1 |

There is abnormal noise when the contactor is running

|

Check whether the contactor core is dusty or the short-circuit ring is broken, remove the dust or replace the contactor.

|

|

2 |

Motor circuit breaker automatically trips |

Check whether the motor is overloaded and grounded.

|

|

3 |

The surface of the power wire connector is overheated and discolored

|

Dispose of the wiring head and tighten the wiring.

|

|

4 |

The motor cannot start

|

Check whether the motor protector operates and whether the power supply is normal.

|

|

5 |

Temperature controller indicates abnormality

|

Whether the parameter settings are correct. Check whether the Pt100 wiring is loose or disconnected, and reconnect the wires.

|

|

6 |

Uncontrolled temperature

|

Check whether the water valve is operating and the pipeline is blocked.

|

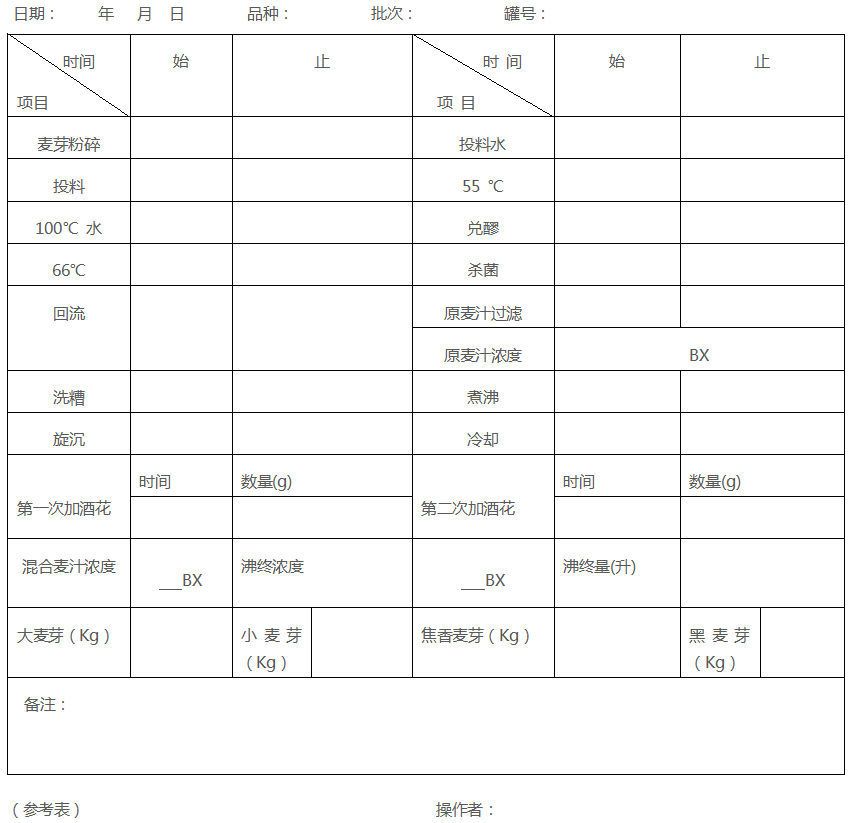

3. Record Form

Table 1

Beer saccharification operation record

Table 2

Beer fermentation process parameter record

日期:年月日品种:批次:罐号:

|

Date |

Time |

Temperature |

Pressure |

Operator |

Remarks |

Date |

Time |

Temperature |

Pressure |

Operator |

Remarks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Reference table) Operator: