Beer is a product with a unique bitter taste among many food and beverages. The soft and pleasant bitterness stimulation combined with the intriguing aroma gives people a pleasant enjoyment.

1. The source of beer taste

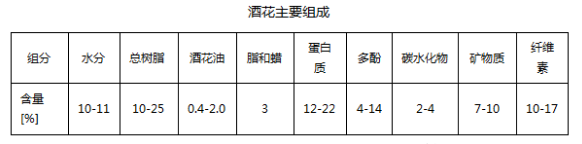

1. Hops:

1.1. a acid (humulone): five homologues: humulone, synhumulone, plus humulone, prohumulone, posthumulone, the content of each humulone is different among different species. The solubility in water or wort is very small, and the decrease of pH during the fermentation process will cause the dissolved a acid to precipitate, attach to the CO2 and the surface of the yeast and be separated. The a acid is converted into iso-a acid during the wort boiling process , It has relatively stable properties in beer and is the main source of beer bitterness. A acid is easy to be oxidized, and most of the oxidation products are not bitter, but the bitterness is reduced and cannot be isomerized. At the same time as the loss of a acid, other bitter substances, hop oil, and polyphenols have almost the same proportion of changes and losses. This oxidative loss can also cause defects in the aroma and taste of the beer.

In terms of providing bitter taste: after isomerization, there are cis and trans forms, cis humulone as the standard bitterness is the most bitter substance, cis heterozygous humulone and trans humulone have the same bitterness, but reverse The bitterness of humulone is the weakest, and the hops with high potassium humulone show a strong retention of bitterness due to the strong dissociation of the isopropyl acid side chain.

In terms of antioxidant capacity: tetrahydroiso-a acid has the most stable bitterness characteristics, followed by cis-isohumulone, dihydro-iso-a acid and trans-isohumulone. Therefore, the flavor aging degree of beer with tetrahydroiso-a acid added after fermentation is the smallest.

During the beer aging process, the iso-a acid is degraded, and the bitterness of the beer will decrease. The trans iso-a acid degrades very fast, and the degradation degree of the iso-a acid within a certain period of time can be expressed by the ratio of trans/cis-iso-a acid.

1.2 Beta acid (lupulone): five homologs: lupulone, combined lupulone, plus lupulone, prelupulone, and postlupulone. It is insoluble, so it does not produce bitterness in beer. Among its oxidation products, Shiluone has a fine and strong bitterness, and its bitterness is similar to that of iso-a acid

1.3. Hop oil: In the late stage of hop maturity, most of the bitter substances are synthesized and formed, and most of them are present in the hop glands.

The aroma of hops in beer mainly depends on the composition of hop oil, rather than its content, which is generally less in fragrant flowers.

The α-acid, β-acid and a series of oxidized polymers in hops are the main components of beer bitterness. α-acid is easily isomerized to form iso-α-acid. Iso-α-acid is the main substance of beer's bitter taste. It has greater solubility than α-acid and has a softer bitterness than α-acid. Boiling under aerobic conditions, α-acids are easily oxidized and polymerized to form γ and γ resins, which are one of the sources of bitterness after beer. β-sour and bitter taste is not as big as α-acid, it is bigger (about 1∕9), it is easier to form β-soft resin, giving beer precious soft bitterness.

2. Malt:

The husk and root of malt.

2. Factors affecting the bitterness of beer

1. Water quality:

Use carbonate or alkaline brewing water, the water SO42- is too much (>70mg/L), Mg2+ is too much (>40mg/L), the heavy metal ions (except Zn2+) and the rest are less than 0.05 mg/L, the saccharification water PH Too high will make the beer dry, bitter and rough.

Control: For water treatment, when GaCI2 is used, the CI ion should be less than 60 mg/L, otherwise the beer will have a salty taste.

2. Hop addition:

2.1 The method of adding hops: three times of adding hops, one pressing bubble, two adding bitterness, and three adding aroma. Add 10% of the total amount for the first time to prevent frothing of the wort. Add 60% of the total amount for the second time to give the beer a refreshing bitterness. Add 30% of the total amount before the third boiling to ensure both bitterness and aroma. And there is it, and prevent later suffering.

2.2 Boiling time: Prolonging the boiling time will not only deepen the color, but also affect the taste of beer.

Adding too much hops or improper adding process, excessive boiling and oxidation will bring heavy bitterness or bitterness to beer.

Control: Choose high-quality hops, add an appropriate amount, adjust the method of addition, and boil in an airtight manner.

3. Yeast autolysis:

Yeast autolysis will produce bitter amino acids, which makes beer "yeast bitter".

Control: Use strong and active yeast, control the composition of wort, oxygen content, fermentation temperature, and cool down normally, avoid rising of wine storage temperature, drain yeast frequently, and store wine for a long time.

4. Wort pH:

Wort pH is high, and the hop bitter resin dissolves more, which will make the beer bitter and make the taste rough.

Control: adjust the saccharification water pH, protein resting pH, washing grain pH, boiling pH.

5. protein:

The protein in wort is not well decomposed, which can easily make the beer bitter and coarse, with "protein bitterness".

6. Oxidation:

The aldehyde groups, hydroxyl groups, alkenes, or enols contained in beer can be oxidized or undergo an oxygenation reaction, resulting in astringency, rough bitterness or post-bitterness, aging and other peculiar smells.

Control: Saccharification, fermentation, filtration and filling strictly control oxygen intake. Such as CO2 back pressure, foaming and foaming to reduce bottleneck air.

7. Hot and cold concretions:

The discharge of the hot and cold coagulum of the wort reduces the α-acid and causes a small loss of bitterness.

8. Boiling strength:

The boiling strength of the wort.

9. Sake filtering:

Diatomite adsorption and foam loss all reduce the bitterness of beer. Adding PVPP also reduces the bitterness of beer

10. Sterilization:

Sterilization strength, high temperature causes the increase of aging substances such as α-furfural and α-acetylpyrrole, which makes the beer taste rough and the bitterness increases.

11. Transportation and storage:

Ultraviolet radiation causes the iso-α-acid to produce optical reflection, cleavage the side chain at the bottom, and react with sulfur-containing compounds to produce substances with sunlight odor.

12. Flavor substances of beer:

Acetoin, acetaldehyde, organic acids, higher alcohols, esters, polyphenols, etc.

13. other:

Caramel can also cause bitter taste; the presence of melanoids can also produce a bitter taste; too long storage can also make beer bitter (increased amyl alcohol); after the fermentation of wort lacking soluble nitrogen, the beer is hard, indifferent and wild. Yeast and bacteria contamination can also cause bitterness.

3. Influencing factors of beer bitterness detection

The main component of the bitter substance in wort, fermentation broth, and beer is iso-α acid. After acidification of the sample, the bitter substance is extracted with isooctane, and the absorbance value is measured at a wavelength of 275nm to determine the relative content of the bitterness value. Bitterness value (BU) is an important indicator of beer products. There are many factors that affect bitterness. At the same sample temperature, our factory conducts a comparative test to test the main influencing factors during the detection process:

1. Error analysis

1.1 The impact of the oscillation effect: it is required to oscillate for 15 minutes to be milky. The frequency of oscillation is not clearly specified. In actual testing, it is found that many people are testing bitterness. The oscillation is not milky. Some think it has little effect, and some Think it has a great influence and is controversial;

1.2 The influence of the centrifugal effect: the requirement is to centrifuge for 10 minutes above 3000r/mim, usually 3000r/mim is selected, but in fact, different centrifuges have different centrifugal radii, and the centrifugal effect is naturally different. It cannot be completely fixed at 3000r/mim. To be determined through experiments;

1.3 Bitterness is a colorimetric analysis. All colorimetric methods require time, and bitterness is no exception.

2. Experiment content:

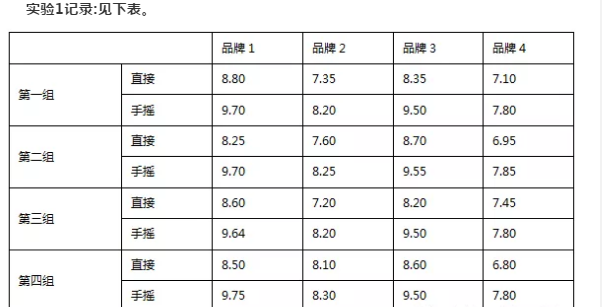

Experiment 1: The effect of shaking extraction

Take 1 bottle each of 4 varieties of wine;

The first group, 2 parallel samples for each of the 4 samples, treat the test samples according to the standard method of bitterness, and shake at 100 rpm for 15 minutes. One of the parallel samples will be directly centrifuged after shaking, and the second parallel sample will be tested after shaking. Shake vigorously by hand until it is milky, and then centrifuge for testing;

In the second group, there are 2 parallel samples for each of the 4 samples. The test samples are processed according to the standard method of bitterness, and shaken at 200 rpm for 15 minutes. One of the parallel samples is directly centrifuged after shaking, and the second parallel sample is after shaking. Shake vigorously by hand until it is milky, and then centrifuge for testing;

The third group, 2 parallel samples for each of the 4 samples, treat the test samples according to the standard method of bitterness, shake at 300 rpm for 15 minutes, one of the parallel samples will be directly centrifuged after shaking, and the second of the parallel samples will be tested after shaking. Shake vigorously by hand until it is milky, and then centrifuge for testing;

The fourth group, two parallel samples for each of the 4 samples, treat the test samples according to the standard method of bitterness, shake at 300 rpm for 15 minutes, add glass beads, one of the parallel samples will be directly centrifuged after shaking, the second of the parallel samples After shaking, shake vigorously by hand until it is milky, and then centrifuge to test;

Analysis: Judging from the above-mentioned test, the appearance of milky form has a greater impact on the test results, and the value of milky form is relatively stable and has good repeatability.

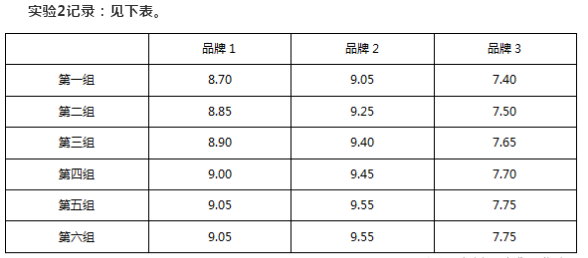

Experiment 2: The effect of centrifugation

Take 1 bottle each of 4 varieties of wine. The samples were processed according to the bitterness method.

The first group, centrifuged at 3000 rpm, 5 minutes;

For the second group, centrifuge at 4000 rpm for 5 minutes;

The third group, centrifuged at 5000 rpm, 5 minutes;

For the fourth group, centrifuge at 3000 rpm for 10 minutes;

The fifth group, centrifuged at 4000 rpm, 10 minutes;

The sixth group, centrifuged at 5000 rpm, 10 minutes;

Experiment 2 Record: See the table below.

Judging from the above-mentioned tests, poor centrifugal effect will also have an impact on the test results. After the centrifugal effect reaches a certain requirement, increasing the centrifugal speed or time will have little effect.

Experiment 3: The effect of detection time

Take 1 bottle of 5 sample wines. The samples were processed according to the standard test method for bitterness.

The first group: test immediately after centrifugation; the second group: test after 10 minutes; test again after 20 minutes;

Experiment 3 record: see the table below.

Analysis: Judging from the above detection, whether to detect immediately, some changes are big, some are not big, and the overall trend is increasing.

4. Conclusion and discussion:

1. About the oscillation effect:

1.1 Being not milky has a direct impact on the test results, not milky, not only the test results are low, but also the repeatability is poor;

1.2 At present, most operators report that it is difficult for a general oscillator to oscillate for 15 minutes to become milky. This requires separate experiments to determine the best oscillation rate. There is also a method to use a special conical flask (cone There are several sharp corners at the bottom of the flask. SAB uses such an Erlenmeyer flask so that the Erlenmeyer flask can be customized);

1.3 There is another method, after the 15-minute shaking is over, immediately shake it by hand until it becomes milky, but the shaking time should not be too long, and be careful not to shake too much to avoid volatilization or loss of isooctane.

2. About centrifugal effect:

2.1 The effect of centrifugation also has a direct impact on the test results. The test results are inaccurate if the centrifugal effect is not good, and the repeatability is poor;

2.2 The standard stipulates that it is more than 3000r/min for 10 minutes. Many factories understand that it can only be 3000r/min. In fact, the centrifuge radius of each factory may be different. The same is 3000r/min. Some can achieve complete centrifugation, and some The centrifugation may not have been completed. Each factory should do experiments to determine the best centrifugation rate. Don't set it as 3000r/min. The sign of a good centrifugal effect is that if the centrifugation rate is increased, the test results will not change.

3. About detection time:

3.1 It should be tested immediately after centrifugation. If it is placed for too long, it will affect the accuracy and repeatability of the test results;

3.2 There should not be too many samples for each test, generally no more than 4 samples are appropriate, so as not to affect the timeliness of testing;

3.3 During the period from centrifugation and taking out to the test, pay attention to the stable placement of the sample and do not shake, so as not to affect the test results.

4. How to use our factory to detect bitterness:

Undegassed beer 10ml, 3N Hcl hydrochloric acid 1ml, add isooctane 20ml, mix into a 250ml iodine measuring flask, shake on an electric oscillator (amplitude 30mm, frequency 120) for 15 minutes and shake it by hand until it becomes milky, transfer 50 ml In a centrifuge tube with a stopper, centrifuge for 10 minutes at a speed of 5000 rpm, and use isooctane as a blank at 275 nm to determine the absorbance value A of the sample isooctane extract. (BU=A×50).

5. Matters needing attention during testing:

5.1 The sampling is representative; the sample temperature is appropriate;

5.2 The glassware used must be clean; the cuvette must be dry, clean, and matching:

5.3 When adding isooctane, shake the iodine measuring flask at a constant speed to make it milky:

5.4 Test immediately after centrifugation